3d-printing

There is a range of 3D printers available in the teaching lab to produce quick prototype structures made out of various plastics.

We have a number of BAMBU and LULZBOT 3D Printers

All of the printers use fused filament fabrication technology (FFF).

Software For Creating Model

There are a number of different packages on the market that you can design your model however we recommend Designspark Mechanical or Solidworks both are installed on the laboratory computers.

The file format the printers require is an STL.

Designspark Mechanical

This is a freeware design package produced by RS Electronics, it is very easy to use and we recommend this for anyone new to 3D design and printing. It may not have all the powerful features of the advanced packages but the learning curve is small and you can turn out designs very quickly.

https://www.rs-online.com/designspark/mechanical-software

Solidworks

This application is a Professional advance 3D / 2D CAD package. You can design, animate and introduce environmental variables to your design. I would not recommend this for the 1st time designer that has never touched a cad package; if you put the time in to learn Solidworks the models\designs you create will be heading towards a professional level and lots of companies and workshops use this package so it is well worth the time learning if you have it.

http://www.solidworks.co.uk/sw/products/3d-cad/solidworks-standard.htm

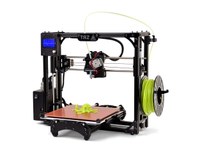

LULZBOT TAZ

The Lulzbot Taz printers are large form factor printers thus they can print large objects. Maximum build size is 250mm x 250mm x 200mm.

The Lulzbot Taz printers are large form factor printers thus they can print large objects. Maximum build size is 250mm x 250mm x 200mm.

The Taz 4 is setup to print with a rubber material (NinjaFlex). This material is highly flexible and strong allowing the creation of flexible parts.

The Taz 5 is setup to print sold plastics like PLA, T-Glase, Nylon, etc

Materials available

- PLA

- T-glase

- NinjaFlex